Technology and processes within a smart factory

The technologies and processes used differ depending on each facility. Accordingly, there is no golden rule for integration and application. The most important core technologies in smart manufacturing include:

Intelligent sensors

By means of sensors on production goods, machines, and other equipment, the production quality of the entire factory can be monitored in real-time. Central process parameters are compared with sample values. If there are deviations in these values - for example during production - it is possible to intervene early and initiate countermeasures.

This reduces production errors and the resulting waste. In connection with predictive maintenance, the sensors provide precise data on when a machine should be serviced. Production stoppages due to machine failures or high maintenance costs can be avoided.

Digital twin

A digital twin represents almost real-time digital images of physical properties and objects such as machines, tools, production goods, robots, and even factory buildings. Based on data analysis, simulations of possible scenarios can be generated using the digital twin.

In this virtual world, predictions about results can be made without affecting the real production of the smart factory. This saves valuable time and protects the physical process from possible errors.

Assistance systems

Assistance systems such as autonomous transport systems or robotic solutions are already widely used in industrial production. As an extension of lean approaches, they are intended to relieve employees of physical and time strain, especially in routine tasks, so that they can concentrate on decision-making at a higher level.

Big Data analysis

In a smart factory, there is a huge flow of data - machines, products, departments, and other potential external sources generate data in various formats. The use of this data forms the basis for the technologies mentioned above. Therefore, the strategy for dealing with Big Data is very important. The data must be processed, analyzed, and intelligently used in decision-making processes. In other words: Big Data must be transformed into Smart Data.

What does a successful transition to a smart factory look like?

As already mentioned, the path to smart manufacturing varies from company to company. Likewise, each smart factory will be structured differently. However, there are five components that are the same for everyone if implemented successfully:

1. Data and algorithms

A smart factory lives on data. You control all processes, make decisions, warn of errors, and can make proactive predictions with the help of the digital twin. Creating, collecting, managing, storing, and, above all, analyzing the strategy and means of data flows and then reacting to them is a basic requirement for the successful path to smart manufacturing. Over time, these data sets are becoming larger and larger and are covering more and more processes.

Analysis, storage, and management capabilities should always be adapted to the requirements when scaling the smart factory. Real-time data visualization can present the captured data transparently. This enables the company to make more accurate decisions.

2. Technology

One of the most important characteristics of a smart factory is connectivity. Only in this way can smart manufacturing function. The complete plant as well as individual machines, products, and other devices are connected to each other and a central control system to communicate with each other. This enables, for example, real-time data exchange between supplier and customer or more efficient cooperation between production and product development.

However, other technologies such as AI, augmented reality, or additive manufacturing should also be considered depending on the application. The number of underlying technologies and software of a Smart Factory can quickly increase. Application Portfolio Management helps you to keep track. You can save any costs for unused technologies in your portfolio, avoid possible legal infringements, and ensure that applications can be integrated into the current IT landscape as easily as possible.

With intelligent technology risk management, you also determine the functional fit and business criticality of each IT component and create cross-regional and cross-facility standards.

3. Process and control

Self-optimization, self-adaptation, and autonomous operation of production are among the core features of an optimized and agile smart factory. Many decisions are made by machines without human intervention. This fundamentally changes traditional processes and administrative tasks. These must be adapted accordingly.

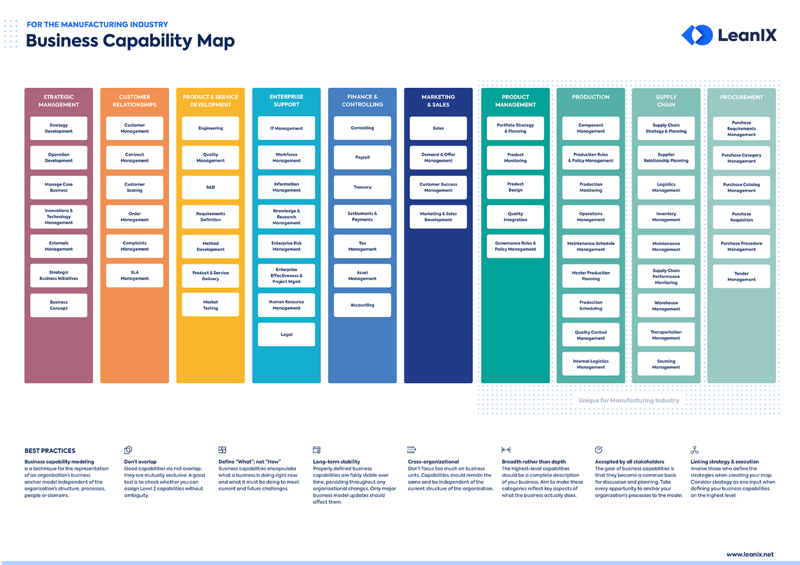

Closer networking with suppliers, customers, and other factories also requires new control models and process optimization. Decision-making processes must be rethought and redesigned in order to respond optimally to these changes. Business Capability Mapping creates a basis for discussion and planning that shows what measures need to be taken to meet current and future requirements.

4. Employees

Even if smart manufacturing means that many processes are automatically controlled by machines, employees are still the key to operations. However, roles and responsibilities will change. Some positions will no longer be necessary as they will be replaced by automation and AI. Other positions could be enhanced by new capabilities such as augmented reality or data visualization.

The change in roles and responsibilities of employees requires adaptable change management to motivate, develop, and train the workforce and to create innovative recruitment approaches.

5. Cybersecurity

The cybersecurity challenge mentioned above should be included as a priority in the strategy for implementing a smart factory from the outset. Especially when it comes to scaling beyond the factory level, a roadmap for technical security is extremely important.

Always with the approach: think big, start small, and scale quickly. The implementation can be as agile and flexible as the concept itself. Whether you start with a single plant or several connection points is up to you. However, it is recommended to start with one system in order to check the concept in advance in a manageable test environment. The positive results can then be transferred to other plants and factories.

Conclusion

Smart factories are the future, if not already the present. In order to remain competitive in the long term, companies should start the lengthy process of transformation or redesign now. At the very beginning, there is a vision and the strategy derived from it, which leads step-by-step to the goal. It is important to always keep an eye on the increasing demands on IT.

The increased use of technologies and the increasing networking of production sites with suppliers and customers requires a comprehensive strategy that optimally connects all components and ensures the future adaptability of the system.

Reducing IT applications to the bare essentials and standardizing applications across companies are core tasks of the LeanIX tool. We have already applied this successfully at NORMA Group.

/EA-Manufacturing-WhitePaper_Resource_Page_Thumbnail.png?width=260&height=171&name=EA-Manufacturing-WhitePaper_Resource_Page_Thumbnail.png)

/EA_24Views_Manuf_Industry_Poster_Resource_Page_Thumbnail.png?width=260&height=171&name=EA_24Views_Manuf_Industry_Poster_Resource_Page_Thumbnail.png)